The plastic PVC pelletizing machine developed and manufactured by plastic is suitable for recycling and granulation of PVC cables, PVC pipes, PVC films, PVC canopy cloths and other plastics, so that their waste plastics can be recycled. PVC granulation equipment generally uses a conical twin screw extruder or a single screw plastic granulator for extrusion granulation, using an air-cooled grinding surface pelletizing system, followed by linking air transmission and vibrating screen.

Features:

- Plastic PVC pelletizing machine uses steam heating to humidify, improve the temperature of the granulated material itself, reduce the granulation moisture, reduce the dryer load, and improve the work efficiency.

- Plastic PVC pelletizing machine uses rotary drum granulator granulation rate of up to 70%, and the equipment is simple to operate, the work flexibility is large, and the maintenance is convenient.

- Plastic PVC pelletizing machine reduces the phenomenon of material sticking to the wall, saves labor, and prolongs the service life of the granulator.

Applications:

Extruder

The pet bottle granulator’s specialized single screw extruder is used to gently melt pre-compacted materials. Plastic waste bottles will melt and plasticize well in the 36D processing section. And the equipment adopts a dual-zone vacuum degassing system, which can effectively remove volatiles such as low molecules and moisture, and is especially suitable for reprinting film and water-containing materials.

PVC particles

The operation is simple and convenient, and the particle size is uniform and beautiful.

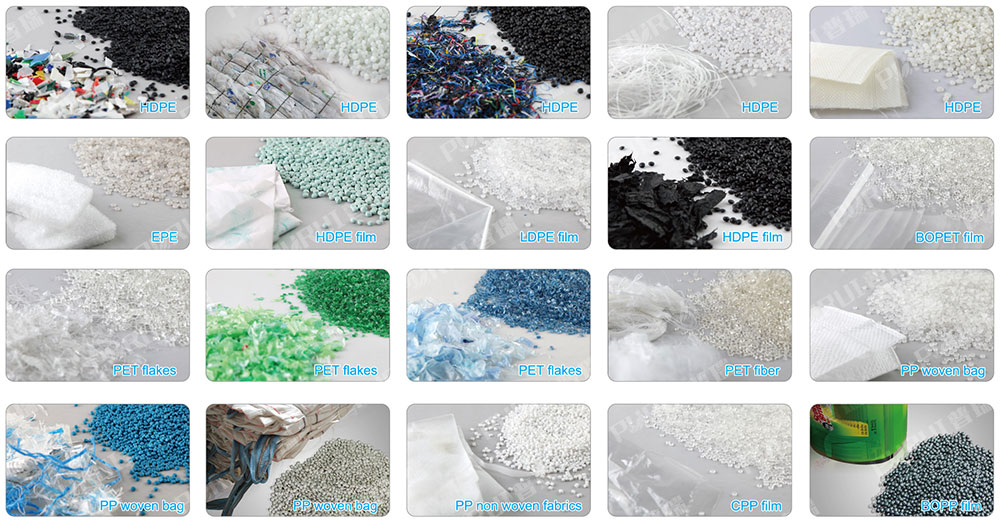

Material