PET pelletizing machine adopts building block principle design, its screw configuration, cylinder structure, length-to-diameter ratio, number of feeding and exhaust positions, net change and pelletizing mode, automatic control mode of electric instrument, etc. can be adjusted according to the material system and process changes, realizing a wide range of multi-functional, multi-purpose versatility and adapt to specific requirements of the unified balance. Low vibration, low noise, PET flake granulation equipment can be installed without foundation, placed on a flat ground.

PET pelletizing machine adopts traditional relay electrical control, temperature control is advanced digital temperature control meter PID adjustment, host, feeding to achieve interlocking control, the operation panel has heating disconnection alarm and main auxiliary machine operation, alarm indication, etc., button operation.

Features:

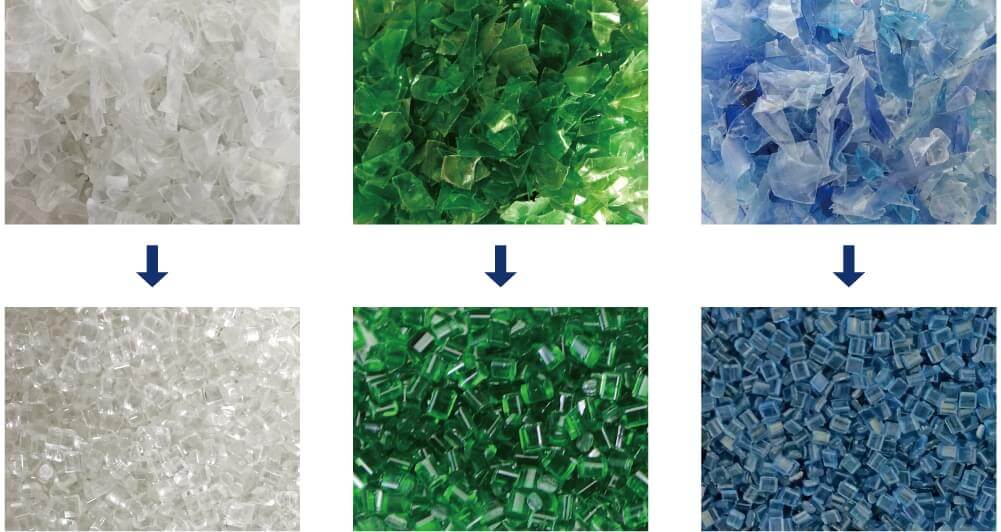

- After processing and cleaning, pet bottle flakes are granulated, and the moisture content is within 5%.

- 3-stage exhaust plus Rhodes vacuum pump, good exhaust effect.

- It has excellent mixing performance, good self-cleaning type, flexible modular combination characteristics. PET bottle flakes granulation equipment does not require a complex precrystallization drying system, which can achieve ideal PET viscosity control, small IV drop, and the addition of appropriate additives can achieve viscosity.

Application:

Parameters:

Co-direction twin screw extruder

| Screw diameter(mm) | 50.5 | 62.4 | 71.2 | 71.2 |

| Screw speed(rpm) | 500/600 | 500/600 | 500/600 | 500/600 |

| Main motor power(kw) | 55/75 | 90/110 | 132/160 | 200/250 |

| Screw length-to-diameter ratio(L/D) | 28-48 | 28-48 | 28-48 | 28-48 |

| Production capacity(kg/hr) | 120-280 | 180-400 | 250-650 | 500-1200 |

Extruders

It is composed of a gearbox (high torque, low noise, external cooling circulation system), a nitrided 38CrMoA1 screw, a barrel (38CrMoAlA, nitrided, cylinder fan cooling, controlled by a temperature control meter), and a vacuum system.

Pull strip pelletizing system

The strip pelletizing system includes a cooling sink, strong air drying and a pelletizer that cools the plastic strips pulled out by the extruder.

Vibration drying system

Advanced dehydration vibrating screen combined with horizontal centrifugal dehydration, high drying granule performance, low energy consumption.