PET bottle recycling washing line is used in the field of PET waste bottle or sheet recycling. PET bottle washing line go through the process of despecification, sorting, crushing, cleaning and drying, and the waste bottle becomes a bottle flake. The washed flakes are widely used in the plastics and chemical fiber industries, such as sheet and profile production, chemical fiber production. Plastic PET bottle recycling machine is mainly used to recycle waste PET bottles, water bottles, Coke bottles and so on. It is washed with hot water for good quality. Wide range of outputs available: 300KG/H, 500-600kg/h, 1000kg/h, 1500kg/h and 2000kg/h…

Plastic PET bottle washing line can easily remove tags, caps, rings, glue, dirt and other impurities, and finally get the ideal PET flakes.

All your requirements for PET bottle recyclers can be customized.

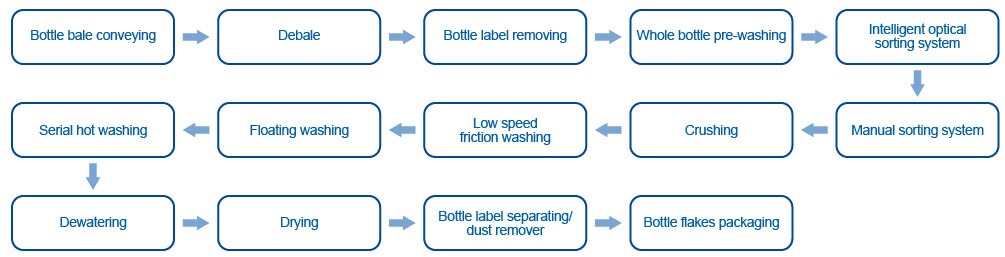

Schematic of the process

Conveyor belt → label removal machine→ sorting table→ conveyor belt → crusher→ spiral loader→ floating scrubbing tank→ friction cleaner → spiral feeder → hot scrubbing tank → high-speed friction cleaner → floating scrubbing → dehydration machine → hot air dryer system → zigzag air classifier system → silos

Advantages of PET bottle washing line

- Save labor. The unpacking and feeding systems we offer will feed evenly.

- You can use a manual sorting system to select bottles and non-PET materials in different colors

- A metal detector is available for you to choose from to remove any kind of metal from a PET bottle

- The specially designed PET bottle granulator can easily obtain high yields and wet mesh with water can be used

- Reduced blade wear.

- High-speed dehydrator and drying system will ensure that the final PET flake moisture <1%

- The fin dust collector will remove the final label on the flakes to guarantee the PVC content.

- The washed flakes can be used to produce polyester staple fibers, straps, PET plastic granules, PET transparent films and sheets. Top-of-the-line flakes can also be used to blow bottles.

- PET bottle recycling cleaning lines can be designed according to how dirty the bottle is and ensure that the quality of the final product is very clean.

- PET bottle recycling washing machine producer Sheng Machinery can supply 500 kg / h to 6000 kg / h

Application

- Plastic PET bottle recycling machine is specially designed for the production of PET flakes for fiber.

- Flakes are available in 2-D, 3-D PSF, filament yarn, PET tape, PET sheet or PET film.

- Plastic PET bottle recycling machine can adopt PLC full line automatic control to control the quality of finished products and save energy.

- Plastic PET bottle recycling machine can be equipped with European automatic material sorting system and color sorting system.

- Plastic bottle recycling machine can be customized according to raw materials and customer requirements.

Technical parameters

| Technical parameters | specification |

| Flake size | 10-12mm |

| Moisture content | ≈1% |

| PVC content | < 150 ppm |

| Ph | 7.5 +/- 0.5 |

| Bulk density | 250-400 kg/m3 |

| Characteristic viscosity | > 0.70 |

| Used for | Polyester / PET bundle Polyester / PSF |

Equipment list and feature

The plastic PET bottle washing line include: conveyor belts, label removers (dry or water), sorting systems, metal detection systems, plastic granulators or crushers, sinking and floating wash tanks, hot wash systems, friction washers, dehydrators, heat dryers, label/dust/fin separators and packaging systems.

| Serial number: | Project Name: | function |

| 1 | Open Charter | Feed evenly |

| 2 | conveyer | Feed |

| 3 | Drum sieve separator | Remove sand, stones and other dirty things from the bottle |

| 4 | Conveyor belts | Feed |

| 5 | Label remover | Remove the label from the bottle |

| 6 | Manual sorting table | Organize the remaining labels, leave the different bottles, etc |

| 7 | crusher | Crush the bottle into thin slices |

| 8 | Screw conveyor | Convey materials |

| 9 | The first automatic floating washbasin | Wash floating lids, rings and dirt |

| 10 | The first high-speed friction washer | High-speed friction to wash away dirt |

| 11 | Hot wash tank | Wash and chemically remove glue, oil and dirt with hot water |

| 12 | Screw conveyor | Convey materials |

| 13 | Second high-speed friction washer | High-speed friction washes out dirty and chemical water from the flakes |

| 14 | Automatic floating wash tank No. 2 | Wash away chemicals, floating hats, rings and dirty stuff, |

| 15 | Automatic floating wash tank No. 3 | Wash away floating hats, rings and dirty things, |

| 16 | Horizontal dehydrator | Remove moisture from flakes |

| 17 | Hot air drying system | Dry flakes |

| 18 | Zigzag air classifier | Remove fin dust and small labels |

| 19 | Automated packaging system | Collect the flakes |

| 20 | Electronic control panel | Used to control the entire line |

| 21 | Free spare parts | |

| PET bottle washing/recycling machine/production line/factory can be customized according to your requirements. | ||