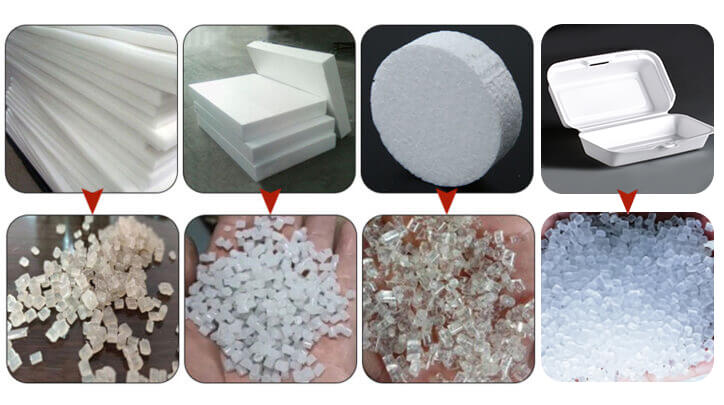

PE EPS foam pelletizing machine, waste foam granulator: also called foam granule machine. The eps foam granulator has a reasonable design, high degree of automation, high efficiency, energy saving and no pollution. It has advanced technology and can directly produce particles at normal temperature, which is uniform in brightness and does not destroy the original molecular mechanism.

The plastic granulation equipment is equipped with a fully automatic control cabinet and PLC operating system, which is easy to operate and has stable performance. Plastic granulator has the characteristics of low energy consumption, remarkable energy saving effect, high output, mechatronics and so on.

Features:

- 1. The main and auxiliary screw barrels are made of imported high-strength high-quality carbon structural steel, which is durable.

- 2. SJ220 adopts conical screw barrel to speed up the feeding speed and greatly improve the output and quality.

- 3. It adopts the main and auxiliary machine production, the heating temperature is stable, effectively improve the molecular structure of the material, enhance the gas permeability, and the particle quality is obviously improved.

- 4. The EPS foam granulator unit is mainly composed of a broken dry cleaning machine, an extruder and an automatic traction granulator. Automatic feeding, automatic temperature control, automatic dust removal, impurity removal, automatic filter change, no pollution during production.

- 5. The foam granulator is a twin-screw fifth-generation waste foam granulator, which is also a special machine for the foam recovery machine. It is equipped with a computer-type full automatic control cabinet, which is easy to operate and has stable performance.

Application:

Parameter:

Ordinary granulator:

| Output(kg/h) | 120-200 | 200-400 | 400-650 | 600-1000 | 800-1200 |

High output low energy pelletizer:

| Output(kg/h) | 200-350 | 400-550 | 600-800 | 800-1200 | 1000-1500 |

Extruders

It is composed of a gearbox (high torque, low noise, external cooling circulation system), a nitrided 38CrMoA1 screw, a barrel (38CrMoAlA, nitrided, cylinder fan cooling, controlled by a temperature control meter), and a vacuum system.

Water ring die face hot cutting system

Water ring granulation, pelletizing speed is controlled by frequency conversion, including: hot cutting head, split-tap,water ring cover, turret, cutterhead, knife holder, arbor, etc.